Broad experience and know-how

Competencies

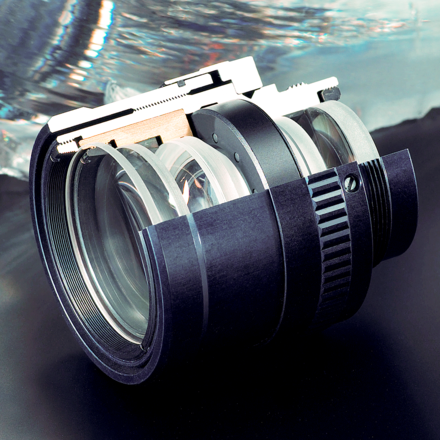

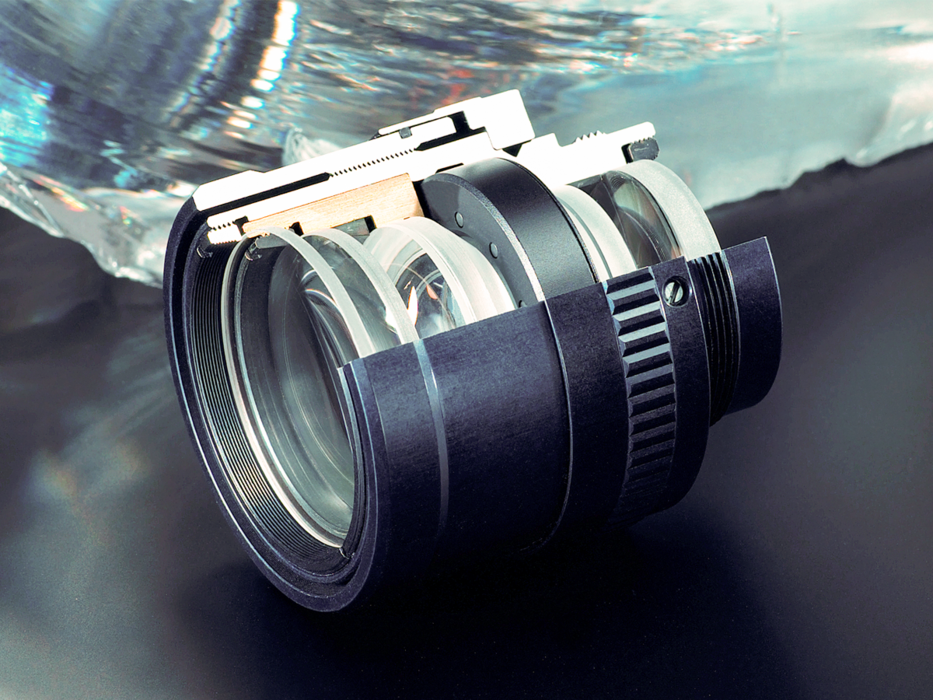

Assemblies

Components for your products

THE PINNACLE OF PRECISION

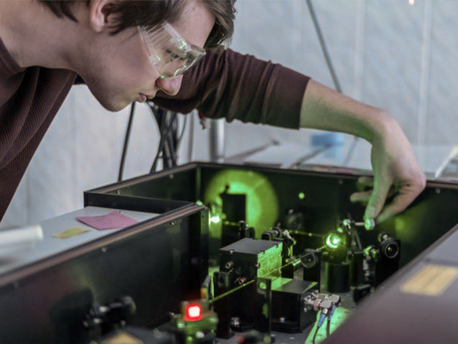

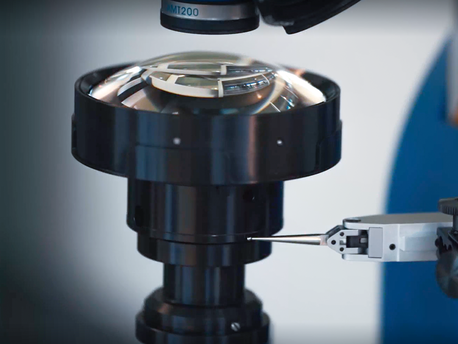

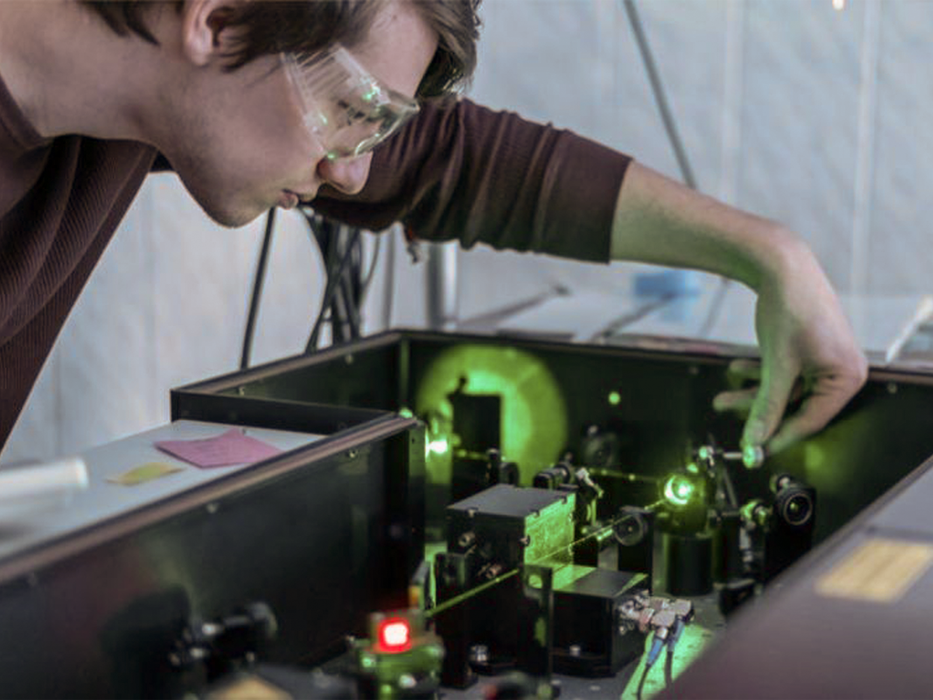

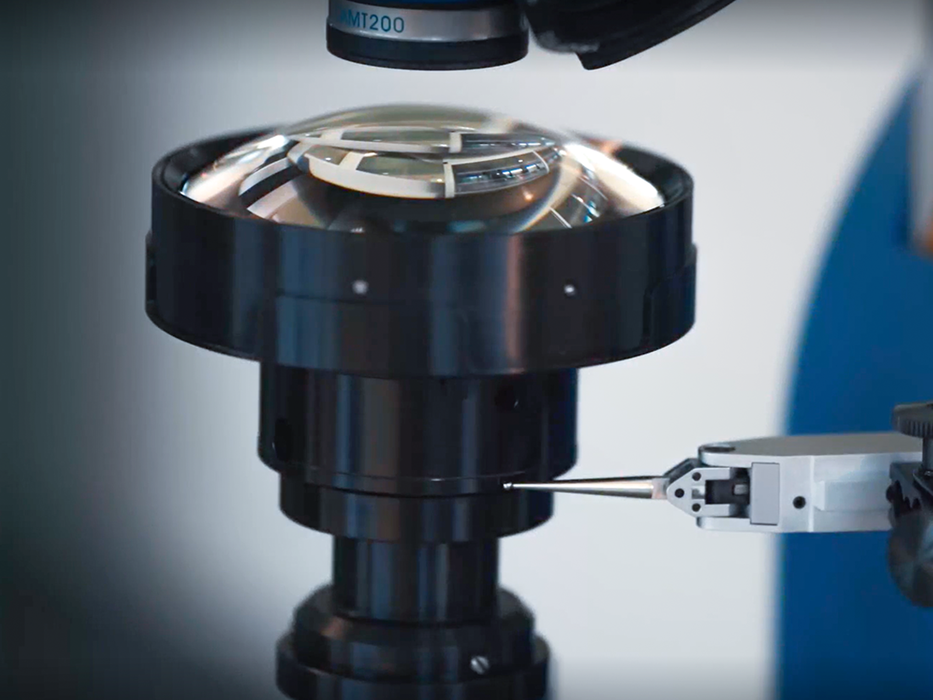

We produce the optical and other components for the well-established instruments of the Haag-Streit Group—in particular, for Haag-Streit slit lamps, which have an excellent reputation in ophthalmology. The final stages of production take place under strictly controlled clean room conditions: precision optical and mechanical components, manufactured in-house, are assembled into high-precision optical systems by our well-trained and specialized staff. All our customers, for whom we manufacture individual assemblies as an OEM supplier, benefit from our decades of experience and the resulting know-how in assembly and alignment.

Quality assurance

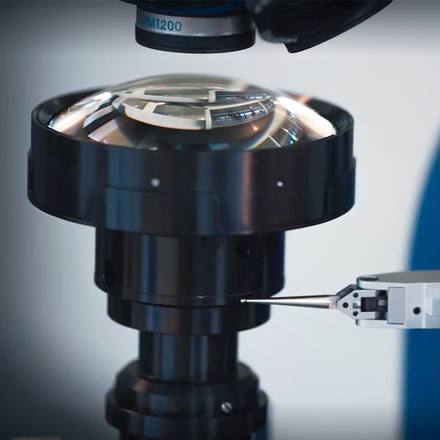

Precision optics

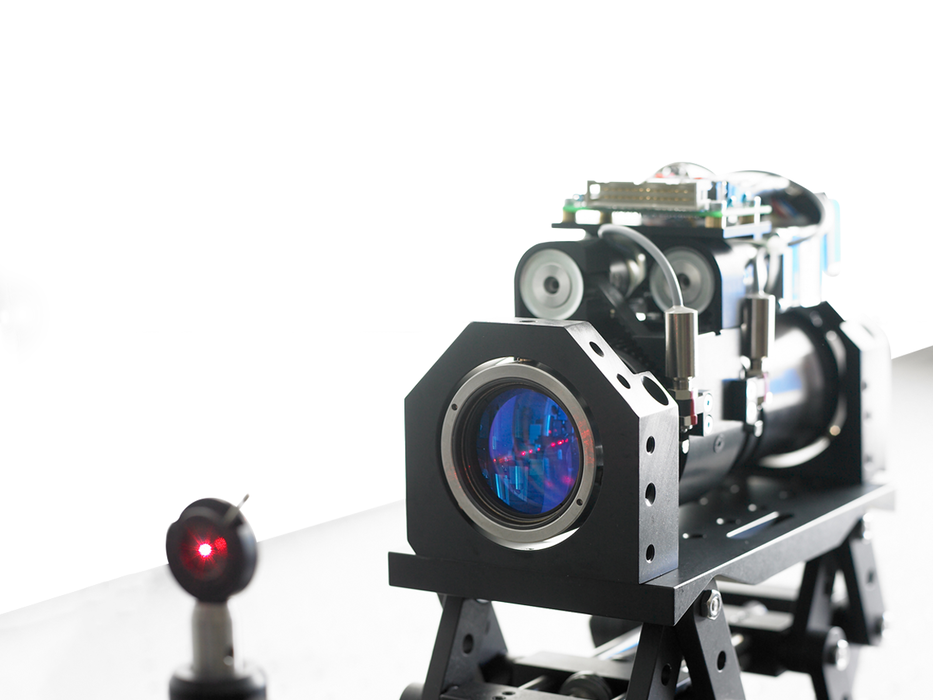

Optical components with first-class performance

Optical components with first-class performance

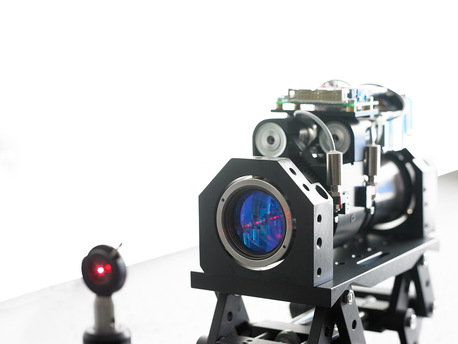

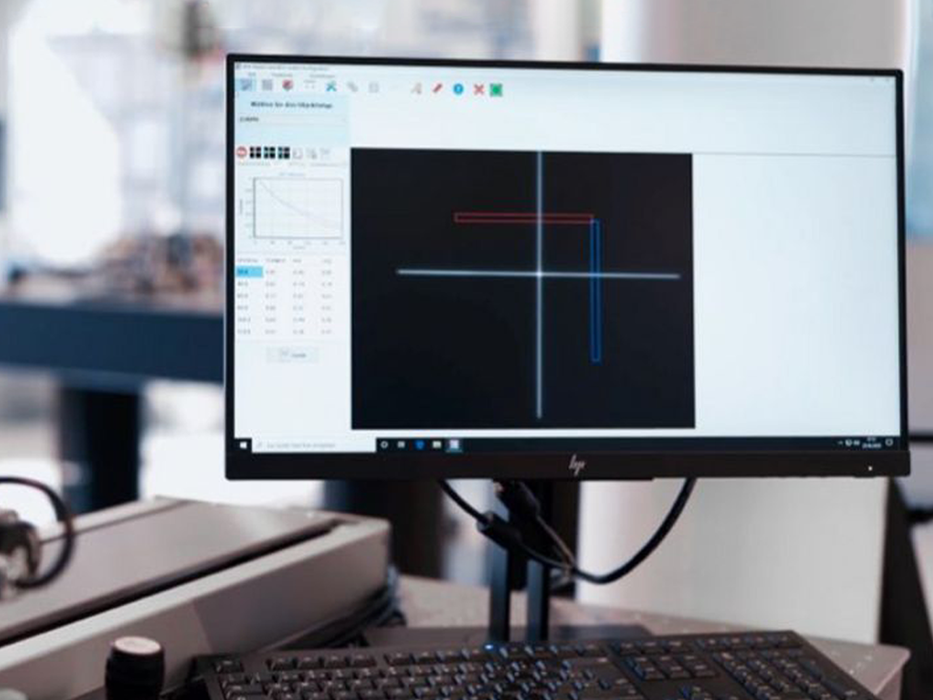

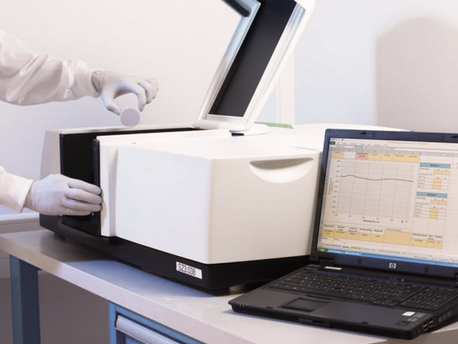

The work of our specialists in precision optics forms the basis of the accuracy of the systems that are created both at Spectros, and those processed further by our customers. Whether a single piece or a series of several tens of thousands of units per year: high-quality raw glass is ground, polished, cemented, centered, and individually coated by us using our in-house coating systems. Using state-of-the-art measurement technology, we ensure that every component that leaves our premises meets its requirements.

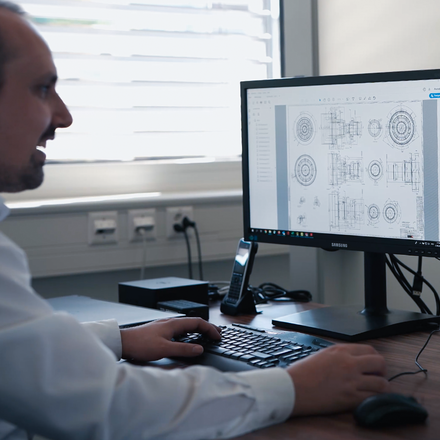

Development

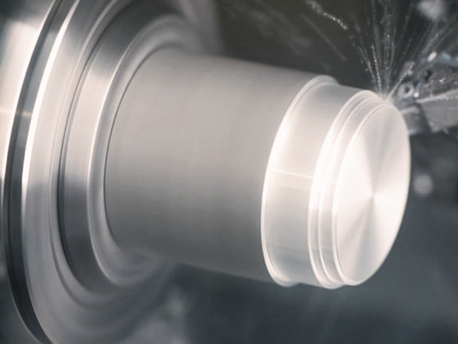

Precision mechanics

In-house production for maximum precision

PRODUCTION FOR ALL BATCH SIZES

We manufacture the mechanical components for our optical systems in-house. Our specialized employees have access to state-of-the-art CNC machinery with turning and milling centers with up to nine axes. An innovative programming system allows the production of highly complex rotationally symmetric and cubic components with unprecedented efficiency. In addition, we have great expertise and sophisticated technical capabilities in the field of finishing, including blue pickling, anodizing, barrel finishing or glass bead blasting.

Our employees know what it means to manufacture high-precision mechanical components for optical systems. They use a special "feeling", which is also used by other manufacturers of optical assemblies.